24000 W. 43rd St

(913) 422-3040

4101 NE Lakewood Way

816-254-5100

112 NE 92 Hwy.

816-532-8288

2265 SE 135 Rd

816-473-3115

Grease Points on the Kubota SCL1000

Properly lubricating pivot points, bearings, and moving parts reduces friction, prevents wear, and ensures smooth operation of this compact track loader. Using high-quality grease as recommended in the Kubota SCL1000 manual minimizes corrosion and extends component life, especially under heavy workloads. Routine greasing, as part of a consistent maintenance schedule, enhances performance, reduces downtime, and protects your investment in the Kubota SCL1000.

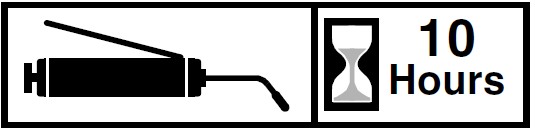

Grease every 10 Hours

Grease Zerks

12- Zerks (Left and right side of the machine)

Quantity: Add grease until grease begins to emerge.

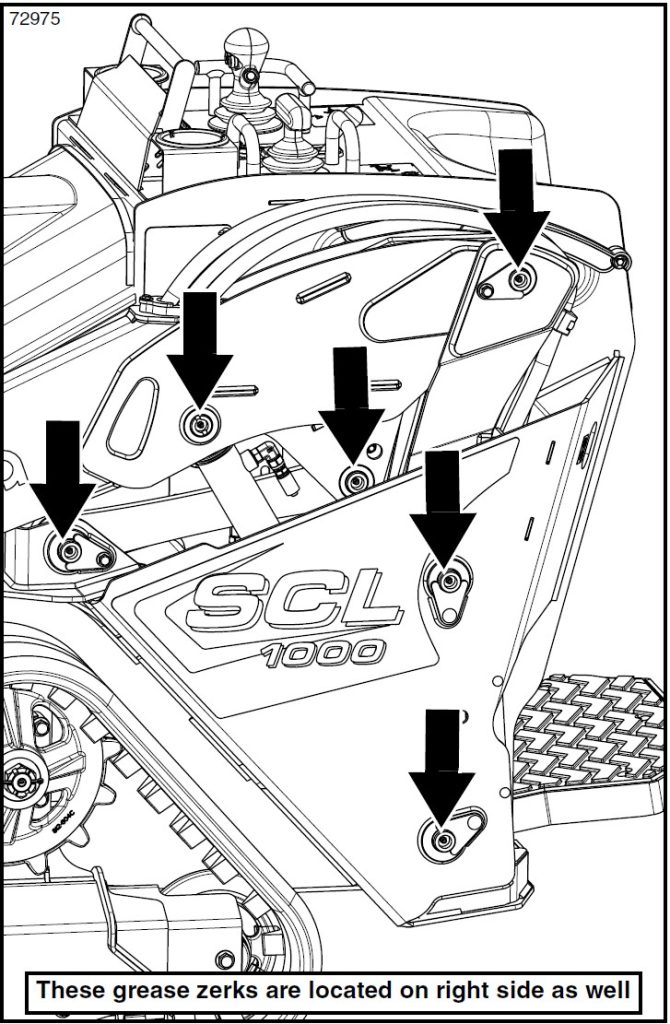

Grease Zerks

1- Zerk

Quantity: Add grease until grease begins to emerge.

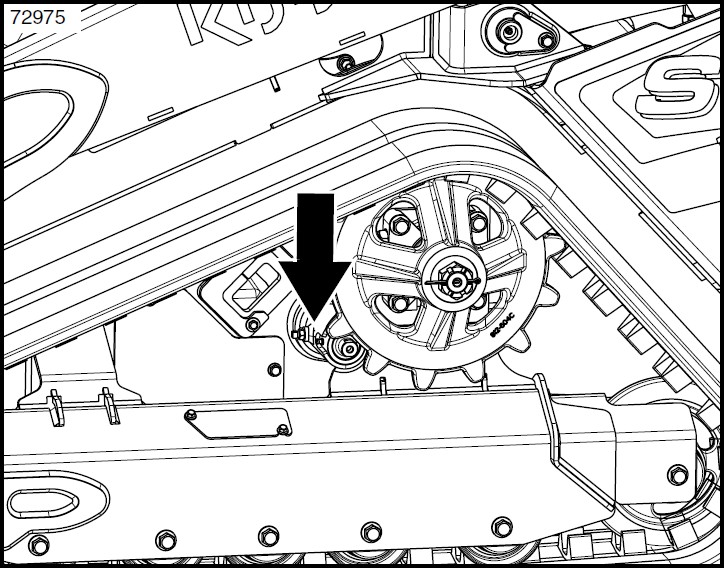

Grease Zerks

6- Zerks

Quantity: Add grease until grease begins to emerge.

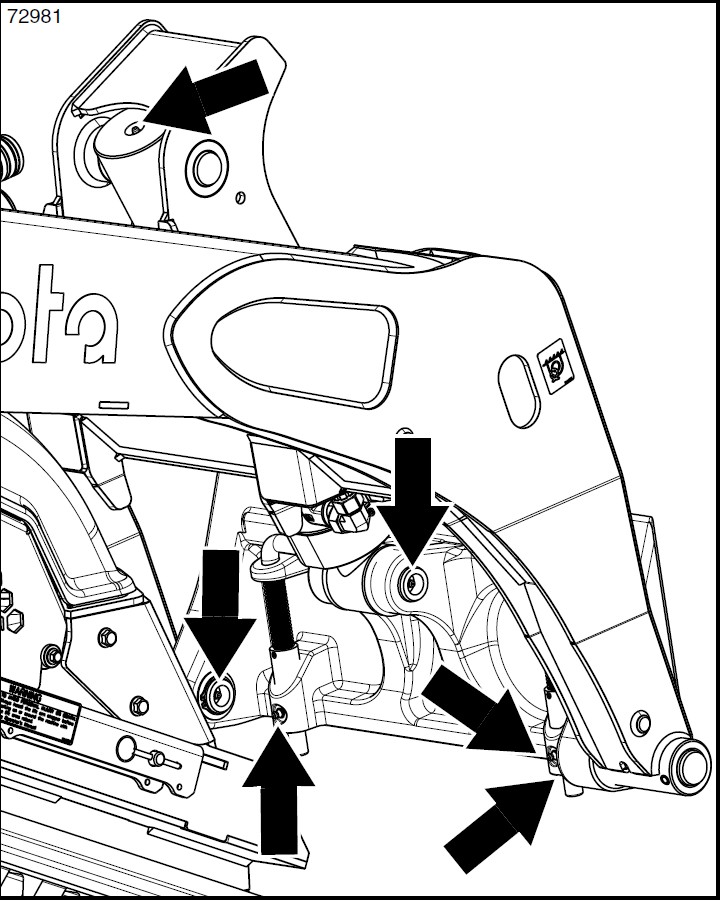

Grease every 50 Hours or as required

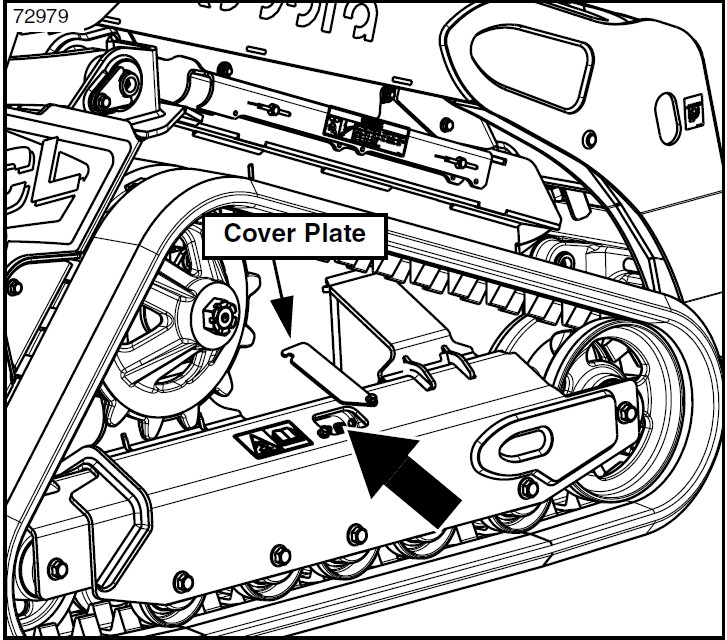

Grease Zerks

2- Zerks (Open cover plate on both sides of machine)

These zerks are for adjusting track tension

Quantity: Add grease until the track is at proper tension.